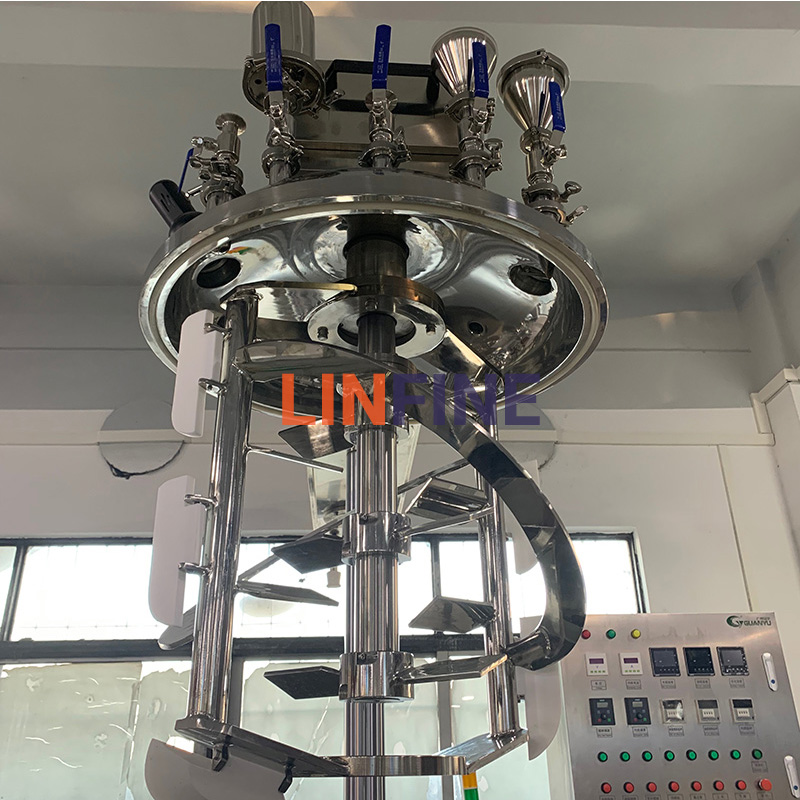

The vacuum emulsifying mixer is expertly designed for producing high-quality creams and ointments in the cosmetics industries. It comprises a pre-treating pot, vacuum emulsifying and blending pot, vacuum pump, hydraulic lifting system, dumping material system, heating system (electric or steam), electric control system, and a working platform. This high shear emulsifier mixer ensures easy operation, stable performance, efficient homogenization, and high production efficiency. Its hygienic design with SUS316L stainless steel for material-contact parts and mirror-polished inner surfaces, meets stringent GMP standards. The hydraulic lifting system is convenient for cleaning and maintenance, while the vacuum defoaming function ensures aseptic processing, particularly beneficial for powder materials. With a high shear homogenizer , it achieves fine emulsification, making it ideal for producing cosmetic creams and ointments.

Brand Motor

Upper mixing motor and bottom homogenizer make pretty fine and smooth cream with high gloss.The ABB or Siemens motor guarantees achieving products fine emulsification.

Homogenizer

To mixing, blending and homogeneous the material when rotating in the homogenizer, widely used in cosmetic cream production for emulsification, homogenization and mixing.

Control Box

The PLC automatic control box includes temperature control, frequency control and time setting control. It makes you reduce numbers of labors and ensures the quality of products.

Technical Parameters

| Capacity | 50-500L or customizable |

| Structure | Water pot , oil pot, emulsifying pot, vacuum system, lifting system, electric control system etc |

| Tank Body | 3 layers of stainless steel mixing tank |

| Material | Internal Layer(Material Contact Part): SUS316L / thickness: 4mm |

| Jacket Layer(Heating/Cooling System): SUS304 / thickness: 4mm | |

| External Thermal Insulation Layer: SUS304 / thickness: 2.5mm | |

| Stirring Method | Using wall-scraping type stirring |

| Mixer Motor(with frequency convertor) Power: 1.5KW | |

| Stirring Speed: 0-60 RPM | |

| Stirring Paddle Material:SUS316L | |

| Homogenizer | Bottom type inner circulation homogeneous form |

| Homogenizer Motor Power:4KW | |

| Homogenizer Rotation Speed: 0-3000 RPM | |

| Homogenizer Material:SUS316L | |

| Open Way | Lifting type top cover |

| Additional Capabilities | Heating or cooling |

| Temperature Display | Electric heating temperature meter |

| Pressure | Jacket design pressure 0.1 Mpa |

| Spare Parts | Electric control box, pipe for feeding(Suck) material, support holder |

Features of Vacuum Emulsifying Mixer

-

High Shear Homogenization

Equipped with a high shear homogenizer achieving speeds up to 3000 rpm, ensuring fine emulsification and smooth, consistent textures.

-

Vacuum Defoaming Technology

Vacuum functionality removes air bubbles during mixing, ensuring high-quality, air-free products suitable for aseptic processing.

-

Hygienic Design

Material-contact parts made of SUS316L stainless steel with a mirror-polished finish, meeting GMP and hygiene standards.

-

Heating or Cooling System

Integrated electric or steam heating system and cooling capability for precise temperature control during production.

-

Customizable Capacity

Available in various sizes and designs to meet different production requirements in cosmetics, daily chemicals and personal care industries.

-

GMP Standard

Designed to meet Good Manufacturing Practice (GMP) standards, ensuring safety, quality, and suitability for regulated industries like cosmetics.

Applicable Products of Vacuum Emulsifying Mixer

-

Cosmetic Products

Face creams, body lotions, serums, gels, and makeup bases.

-

Personal Care Products

Shampoos, conditioners, body washes, and liquid soaps.

-

Skincare Products

Moisturizers, exfoliating scrubs, masks, and sunscreen formulations.

-

Food and Beverage Products

Mayonnaise, sauces, dressings, spreads, and dairy-based products like yogurt and cream.

-

Household Cleaning Products

Detergents, dishwashing liquids, and multipurpose cleaners.

-

Fragrance and Aromatherapy Products

Perfumes, essential oils, and scented body mists.

-

Industrial and Chemical Products

Adhesives, coatings, lubricants, and emulsions.

-

Pet Care Products

Pet shampoos, conditioners, and grooming products.

Reviews

There are no reviews yet.