This stainless steel mixing tank with agitator is expertly designed for producing cosmetics, liquid soap, and similar products with exceptional quality. Its double-jacketed structure supports steam or electric heating, offering precise temperature control for various formulations. Made from premium 304 and 316L stainless steel, the tank ensures outstanding durability, hygiene, and corrosion resistance. Equipped with a reliable brand motor and advanced Germany Fluko technology, it guarantees efficient, consistent mixing. Ideal for modern manufacturing needs, this tank combines performance, reliability, and versatility to streamline production processes.

Brand Motor

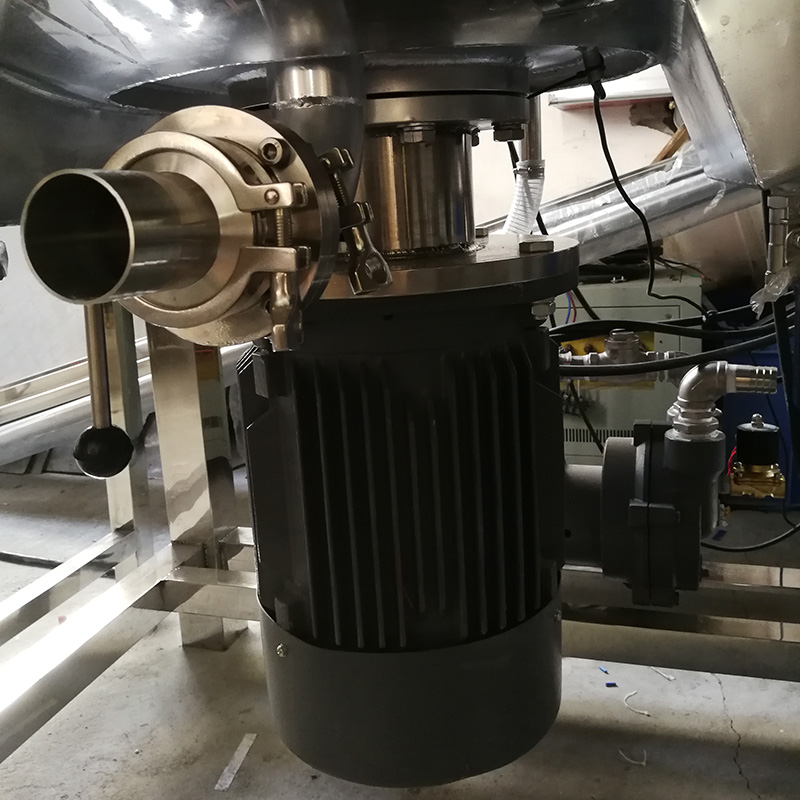

Upper mixing motor and bottom homogenizer make pretty fine and smooth product with high gloss. The motor adopts ABB or Siemens brand. Electric heating or steam heating is optional.

Homogenizer

To mixing, blending and homogeneous the material when rotating in the homogenizer, widely used in industrial production for emulsification, homogenization and mixing.

Control Box

The PLC automatic control box includes temperature control, frequency control and time setting control. This make you reduce numbers of labors and ensure the quality of products.

Technical Parameters

| Capacity | 10-1000ML customizable |

| Structure | Mixer motor, mixing tank, heating/cooling system,electric box |

| Tank Body | 3 layers of stainless steel mixing tank |

| Material | Internal Layer(Material Contact Part): SUS316L / thickness: 4mm |

| Jacket Layer(Heating/Cooling System): SUS304 / thickness: 4mm | |

| External Thermal Insulation Layer: SUS304 / thickness: 2.5mm | |

| Stirring Method | Using anchor type scraping mixing |

| Mixer Motor(with frequency convertor) Power: 1.5KW | |

| Stirring Speed: 0-60 RPM | |

| Stirring Paddle Material:SUS316L | |

| Homogenizer | Bottom type inner circulation homogeneous form |

| Homogenizer Motor Power:4KW | |

| Homogenizer Rotation Speed: 0-3000 RPM | |

| Homogenizer Material:SUS316L | |

| Open Way | Unilateral portable cover open (activity cover) |

| Additional Capabilities | Heating or cooling |

| Temperature Display | Electric heating temperature meter |

| Pressure | Jacket design pressure 0.1 Mpa |

| Spare Parts | Electric control box, pipe for feeding(Suck) material, support holder |

Features of Stainless Steel Mixing Tank with Agitator

-

Hygienic Design

Constructed with high grade stainless steel 304+316L for superior corrosion resistance, easy cleaning, and compliance with strict hygiene standards.

-

Germany Fluko Technology

Integrated advanced technology for efficient, reliable, and uniform mixing performance, ensuring consistent product quality.

-

Customizable Capacity

Available in various sizes to meet diverse production requirements, from small-scale batches to large industrial operations.

-

Double-Jacketed Design

Supports steam or electric heating and cooling for precise temperature control, ideal for sensitive formulations.

-

GMP Standard Compliance

Designed to meet Good Manufacturing Practice (GMP) standards, ensuring safety, quality, and suitability for regulated industries like cosmetics and daily chemicals.

Applicable Industries of Stainless Steel Mixing Tanks

-

Cosmetics and Personal Care

Creams, lotions, serums, shampoos, conditioners, body washes, hand sanitizers, gels, and facial masks.

-

Food and Beverage

Mayonnaise, sauces, dressings, syrups, dairy products, fruit juices, liquid flavorings, and chocolate coatings.

-

Chemical

Detergents, liquid soaps, industrial cleaning agents, adhesives, and chemical solutions.

-

Paints and Coatings

Water-based paints, emulsions, varnishes, and protective coatings.

-

Agricultural Chemicals

Liquid fertilizers, pesticides, and herbicides.

-

Household Products

Dishwashing liquids, floor cleaners, glass cleaners, and air fresheners.

-

Textile Industry

Dye solutions, fabric conditioners, and textile treatment agents.

Reviews

There are no reviews yet.